In the first episode, we accurately analyzed the gear breaking fault of the reducer through the "micro special fault diagnosis multi-dimensional analysis system". Today, we bring you the second episode.

Fault diagnosis test of reducer (II)

The following is a video illustration:

This time, the two reducers on the test bench are also tested. Under the condition that whether the reducer has fault or not and the fault type is unknown, the reducer is analyzed through the diagnosis system, and the conclusion is drawn, and then the reducer is disassembled to verify the correctness of the conclusion.

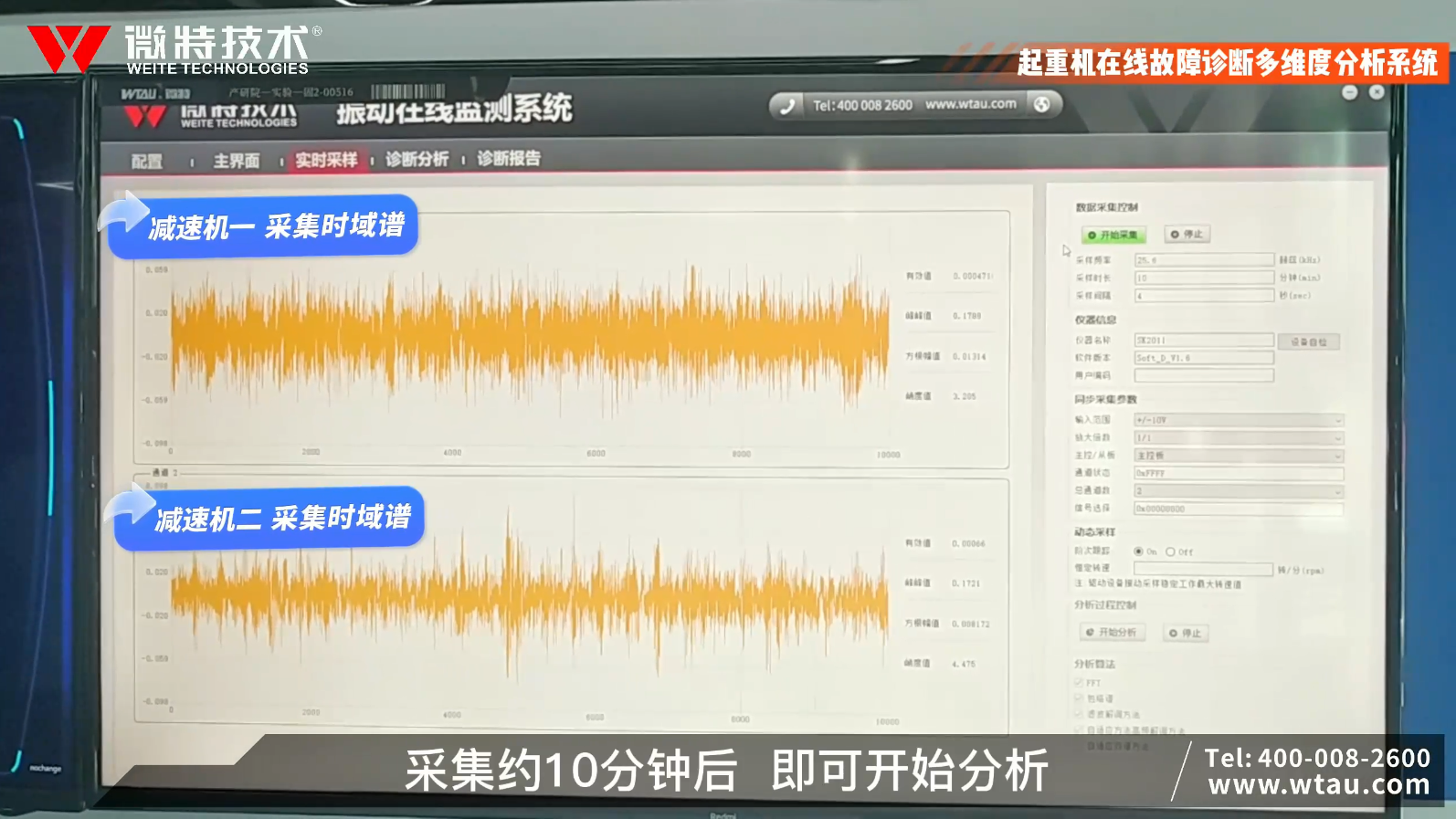

Install the vibration sensors on the two reducers respectively, and start the rotating equipment of the test bench.

The wt-msam integrated data acquisition control module collects the vibration data of multiple sensors in real time, and the analysis can be started about 10 minutes after the data collection.

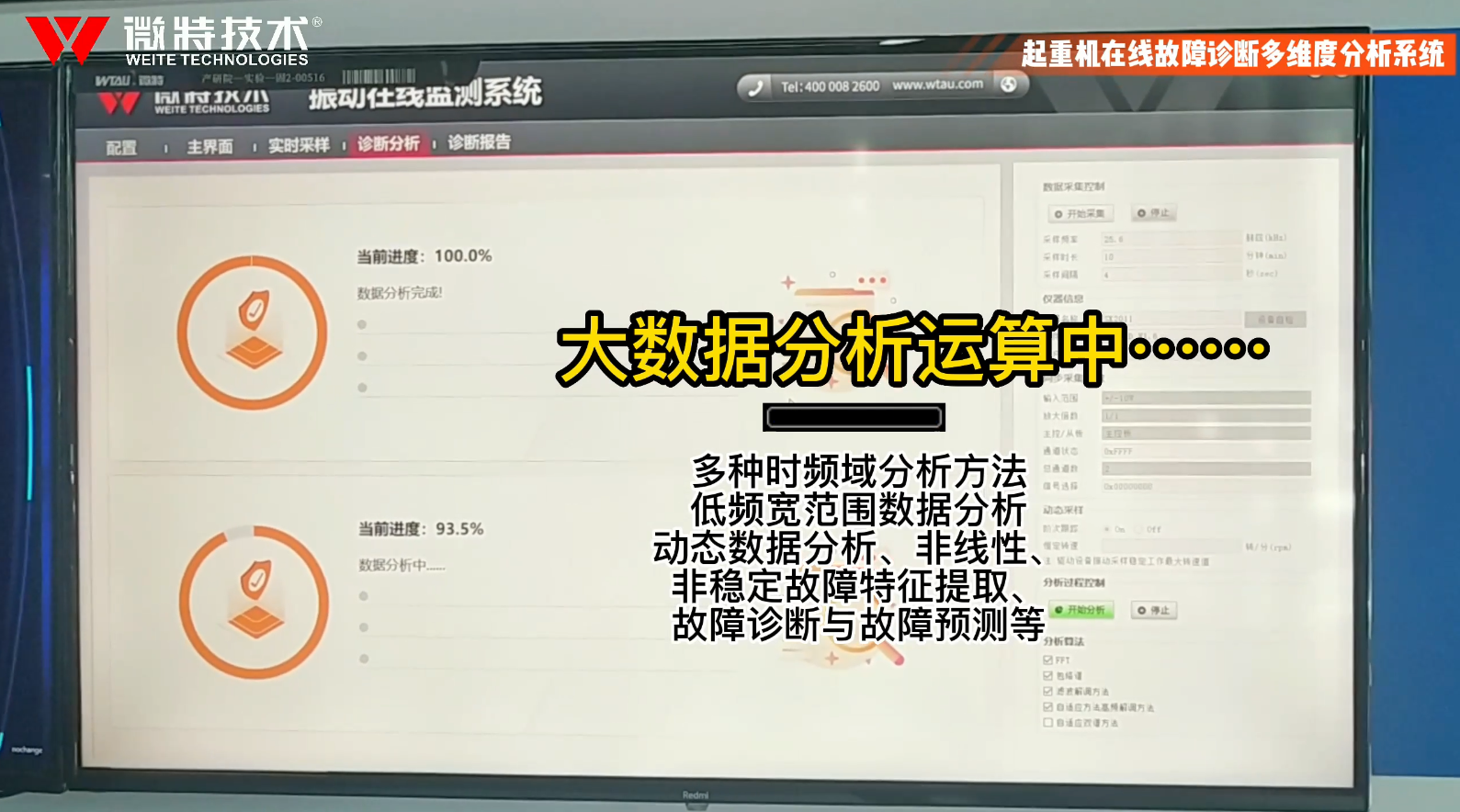

Enter the diagnostic analysis interface, and the system starts big data analysis and operation.

Microtech has developed a series of algorithm toolsets for complex fault synthesis spectrum, integrating multiple time-frequency analysis methods to realize low-frequency and wide-range data analysis, dynamic data analysis, nonlinear and unstable fault feature extraction, fault diagnosis and fault prediction.

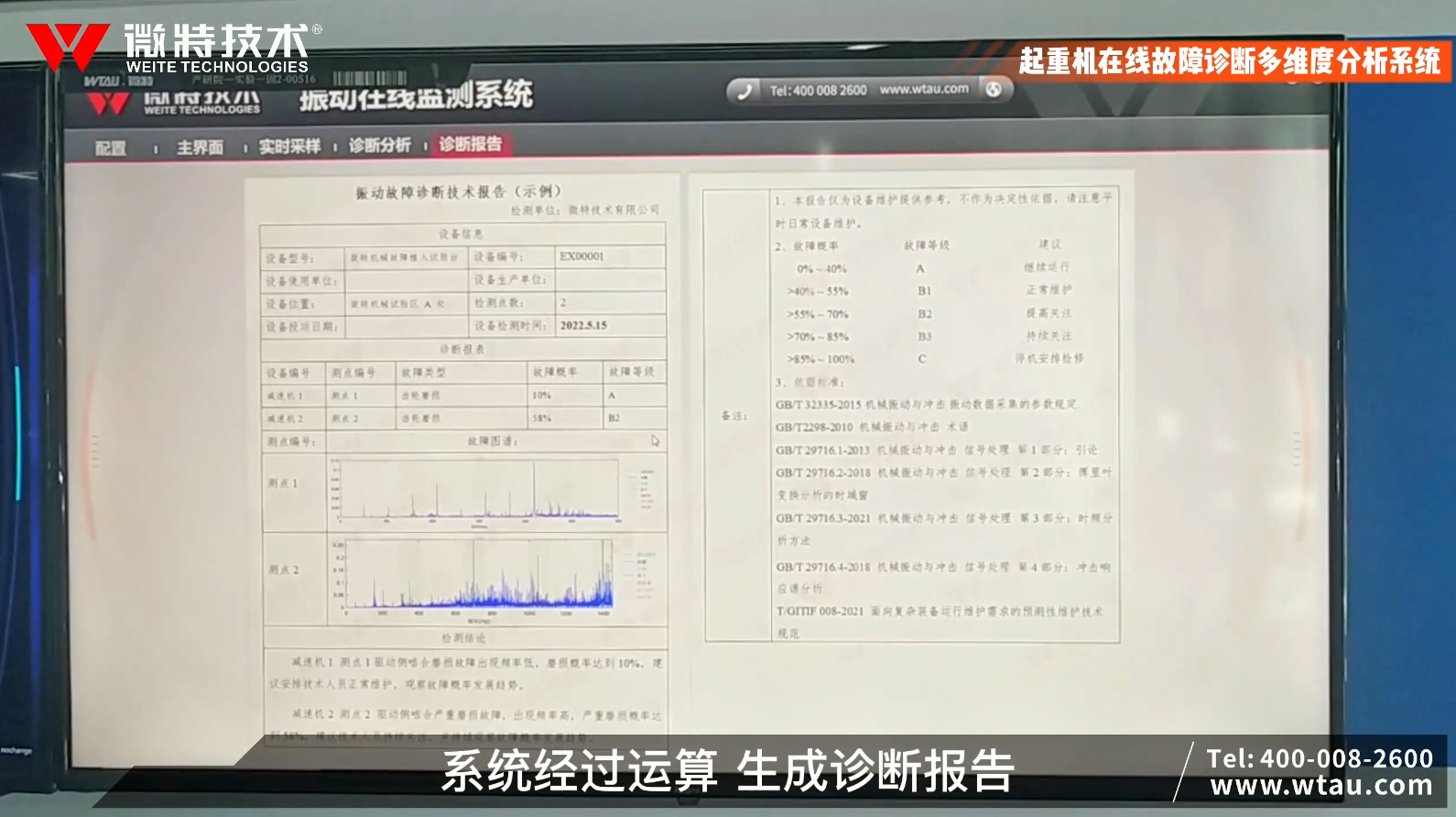

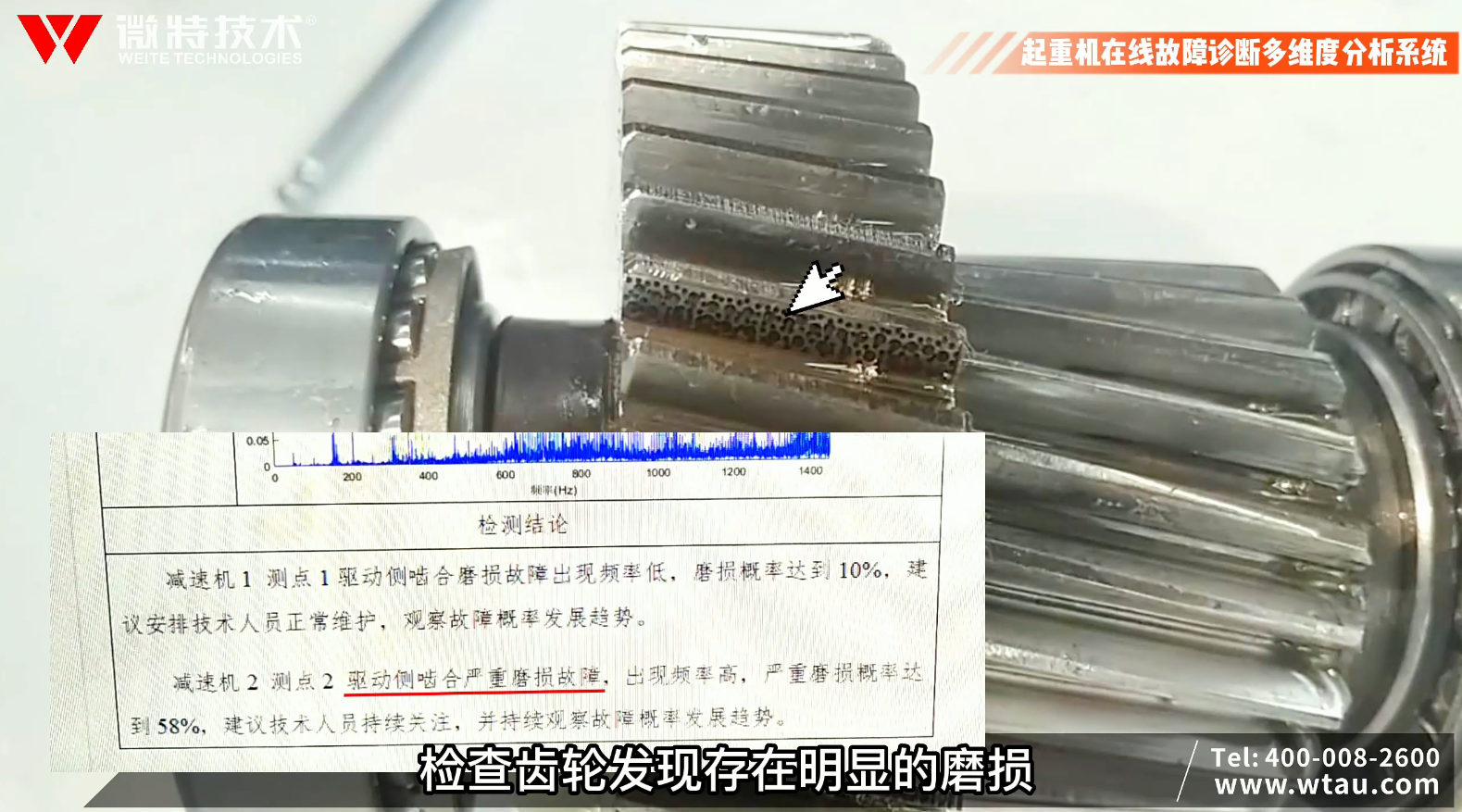

When the calculation is completed and the diagnosis report is automatically generated, we can see in the diagnosis report that the wear probability of the first gear of the reducer is 10%, and the fault level is a. The wear failure probability of the second gear of the reducer is 58%, and the failure level is B2. In the "detection conclusion" column, the fault descriptions of the two reducers are given and the implementation suggestions are given.

Retain the diagnosis results and start disassembling the reducer with a gear wear failure probability of 58%. Open the reducer and take out the gear for inspection.

Through troubleshooting, it was found that the side meshing of the gear was severely worn, which was consistent with the description in the diagnosis report. The system once again accurately analyzed the gear breaking fault of the reducer. We once again tested and verified the effectiveness and accuracy of the "micro special fault diagnosis multi-dimensional analysis system" with practice!

This video once again answers and verifies the questions about how to diagnose the fault of the reducer and whether the diagnosis conclusion is accurate and effective. The next issue will bring you the diagnosis and verification of bearing faults. Please look forward to it!