1、 Overview

Wtyz series underwater hydraulic pump station is specially designed and manufactured for hydraulic automatic grabbing beam, hydraulic trash remover and hydraulic grab of hydraulic and hydroelectric mobile hoist. It is allowed to work at a depth of not more than 150 meters. It is applicable to the control of 5t to 600t single lifting point or double lifting point hydraulic automatic grabbing beam and various hydraulic cleaning grab.

2、 Composition of underwater hydraulic pump station

Oil tank: a device for storing oil, radiating heat, separating air and precipitating impurities in oil and supporting the hydraulic system. It is composed of oil tank body, flow separator, filter screen separator and air filter.

Oil pump and motor: driving device of hydraulic pump station

Hydraulic valves: electromagnetic reversing valve, overflow valve, one-way valve, pressure relay, pressure gauge, filter and other devices.

3、 Main features of underwater hydraulic pump station

Various shapes are suitable for dry hydraulic grabbing beam, cleaning machine, cleaning grab, etc., which is convenient for equipment installation.

The oil pump, motor and hydraulic parts are all well-known brands at home and abroad, with good performance and reliable quality.

Underwater work, water pressure resistance, no deformation, good reliability, internal and external anti-corrosion treatment.

The pump station has been mass produced, with sufficient spare parts and good interchangeability. It can also be customized according to needs.

performance parameter

1. The oil tank of the hydraulic pump station is made of 27SiMn alloy structural steel or A304 stainless steel, with a wall thickness of 8-10mm and designed and manufactured according to the underwater pressure of 7MPa.

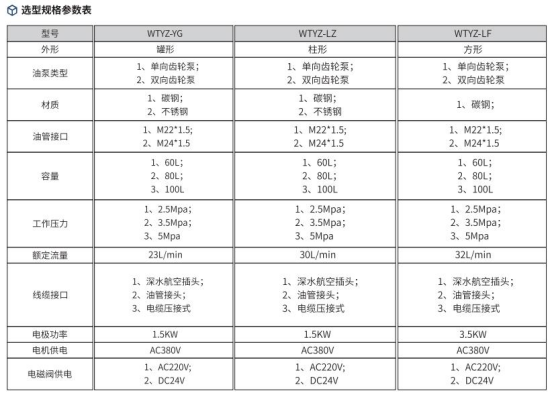

2. The effective volume of the oil tank in the pump station is more than 60L, 80L, 100L and other specifications.

3. Domestic or joint venture well-known gear oil pump brand, rated working pressure: 3.5-5mp; Rated flow: 20L / min; 23L/ min ; 30L/ min ; Etc; The working pressure of the conventional hydraulic system is set at 2.5-3.5mpa.

4. Domestic or joint venture well-known brand motor power motor power 1.5-2.2kw optional, working voltage AC380V.

5. Rexroth, ATOS or Parker electromagnetic; Electromagnetic rated working voltage: AC220V or DC24V;

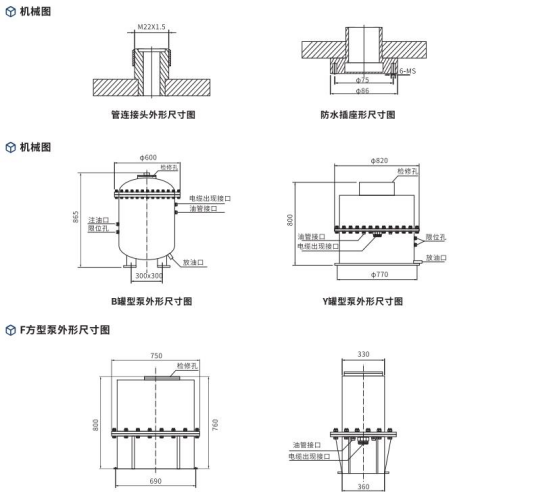

6. Inlet and outlet oil pipe joint M24 / 1.5;

7. The cable outlet of the pump station adopts 1-inch oil pipe butt joint mode and aviation plug mode;

8. 32 low-temperature anti-wear hydraulic oil is selected as the hydraulic oil, which can ensure the normal operation of the system in the environment of - 30 ° C to 60 ° C.

9. Pump station weight: generally 180kg-300kg according to the specification.

matters needing attention

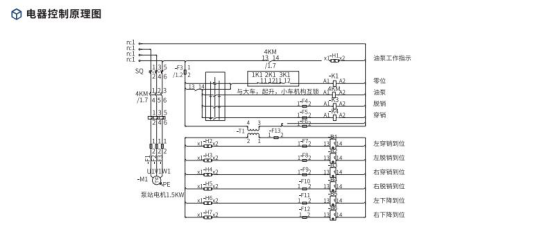

1. When the pump station is selected for the hydraulic grabbing beam; The river is of tank shape, round, square and split type, but the rated pressure is 2.5MPa, and the flow shall not be greater than 14lmin. When the pin diameter is less than 200mm, the flow of 10L / min is recommended. The hydraulic pump of the grabbing beam pump station is divided into a one-way and B two-way. See the reference drawing for its control mode.

2. When the pump station is selected for the hydraulic trash remover and grab; Circular and split type can be selected. The rated pressure is 2.5-12mpa (adjustable). The flow is recommended to be greater than 16L min. the hydraulic pump of the grab pump station has only one-way A. see the reference drawing for its control mode.

3. The control mode of the pump station shall be communicated with our company in time when ordering, and our company shall provide reference drawings.

4. When purchasing hydraulic grab pump station, waterproof socket type shall be selected as far as possible. The pump station does not include waterproof plug and socket. If cables are required, our company can provide them and seal them for free.

Safety operation specification

1. All bolts that have been sealed and tightened shall not be loosened. Once loosened and tightened, the sealing performance will be seriously affected.

2. Before connecting the oil pipe and the connector, it is necessary to check whether the 0-type sealing ring is missing on the connector and whether the sealing ring is intact. After the plug and socket are connected, they must be tightened.

3. The rated oil filling capacity of the pump station is 60L. Please fill it quantitatively and replace the hydraulic oil regularly.

4. When installing the cable joint, pay attention to whether the sealing ring is intact. If necessary, seal the hole with sealant to ensure that the pump station is isolated from the outside.

5. After the installation of the system and before the first use, the automatic grabbing beam (the system) must be sunk into the deepest working water level, and the water surface must be raised after 30 minutes. At the outlet terminal of the control cabinet, use a 500V ohmmeter to measure the resistance to the ground of the oil pump motor circuit. If the resistance value has no obvious change from that before launching, it means that there is no water seepage. Only if there is no water seepage can normal operation be carried out.

6. In actual work, after the automatic hydraulic grabbing beam is lowered in place each time, the grounding resistance of the oil pump motor circuit must be measured with a 500V megger at the outlet terminal of the control cabinet. The pin insertion and pin removal operation can be carried out only when there is no water seepage, otherwise the operation is not allowed.

7. Selection of hydraulic oil: hydraulic oil model; HL-46 or hm-46 is used in normal temperature areas and 10 or 12 aviation hydraulic oil is used in cold areas. The hydraulic oil can be changed once a year according to the service conditions.