The intrinsic safety inspection of traditional lifting equipment mainly relies on manual inspection and scheduled maintenance mode, which is inefficient, unreliable, difficult to manage, and prone to under maintenance or over maintenance incidents.

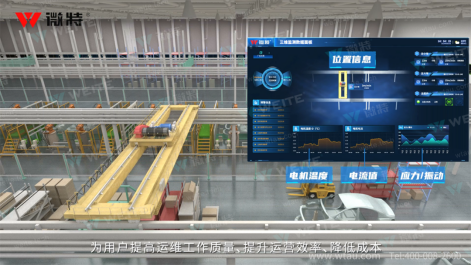

The intelligent operation and maintenance management system for bridge cranes developed and produced by Weite adopts advanced technology and a practical operation and maintenance management mode, achieving improved quality, efficiency, and cost reduction in operation and maintenance work.

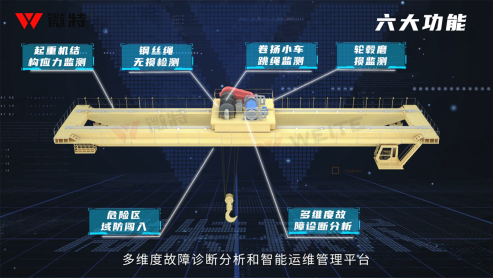

Taking the bridge crane in the stamping workshop of the automobile manufacturing industry as an example, the system mainly consists of seven parts: illegal intrusion of personnel in the working area system, crane stress detection, wheel wear monitoring, wire rope damage detection, winch jump rope monitoring, fault diagnosis analysis, big data software platform, and driver behavior monitoring.

Plan Introduction

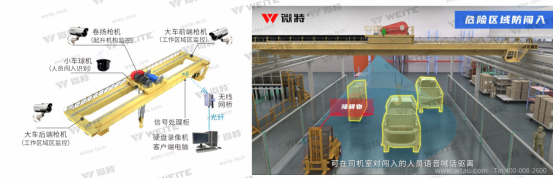

1、Illegal intrusion of personnel in the work area

Due to the complex working environment on site, it is based on an AI vision system. Shoot a video of the scene below the hook using a camera, issue sound and light alarms when entering the hook area, and call out to drive away unauthorized intruders.

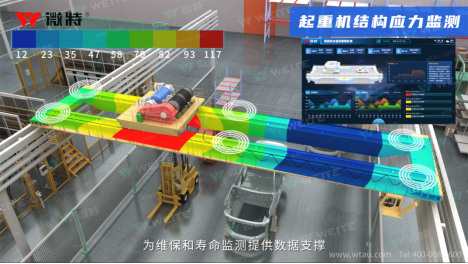

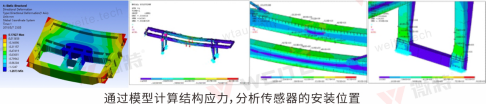

2、Crane stress monitoring

The bridge crane mainly monitors the stress changes of the main beam and end beam, and analyzes whether there is an upward and downward trend in the steel structure and the trend of cracks in the steel structure through the changes in the force points during the operation of the trolley.

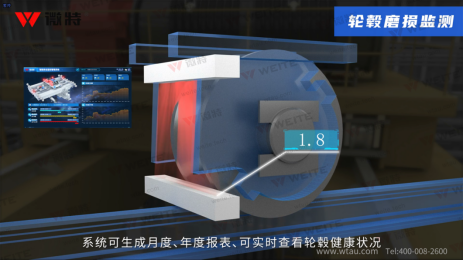

3、Wheel hub wear monitoring

Weite has developed a wheel wear monitoring system that can set the usage threshold of equipment wheels. When the equipment wheels reach the threshold, the equipment will sound an alarm, reminding maintenance personnel to carry out equipment maintenance plans.

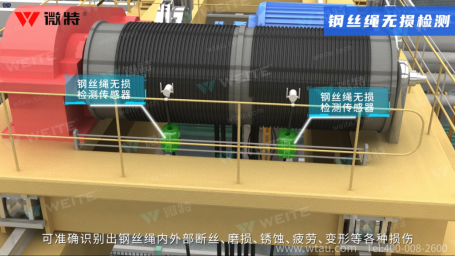

4、Online detection system for steel wire ropes

The online detection equipment for steel wire ropes collects data on the status of in-service steel wire ropes, accurately identifying various damages such as broken wires, wear, corrosion, fatigue, deformation, etc., achieving online monitoring of the status of steel wire ropes and analyzing the degree of damage.

5、Rope skipping monitoring of winch trolley

A visual system based on AI video learning and algorithms. The main method is to capture the working video status of the on-site winch through a camera, and analyze the abnormal status of the steel wire rope during the operation of the winch through algorithm software implanted on the PC.

6、Fault Diagnosis System

Perform online diagnostic analysis on the rotating transmission components such as motors, reducers, and bearings of the workshop overhead crane. The system supports synchronous acquisition and diagnosis of multiple devices and measurement points.

7、Big data software platform

Weite Technology has developed a big data monitoring platform based on the pain points during the operation of cranes, established an equipment production, operation and maintenance guarantee system, and used advanced IoT sensing technology and intelligent software algorithms to complete unmanned and autonomous inspection of equipment intrinsic safety, reducing the difficulty, intensity, and workload of point inspection and operation work. Information transmission is digitized, and process management is streamlined.

We provide you with valuable solutions! The intelligent operation and maintenance management system for bridge cranes can customize solutions according to user needs. For detailed information, please consult with Weite technical engineers.