Bridge erecting machines, as lifting equipment for erecting prefabricated beams, are widely used in highway and railway bridge construction projects. As large-scale special equipment, the risk factor has always been high in complex and ever-changing construction environments, and major accidents such as overturning and overturning are not uncommon.

1. Application Scenario

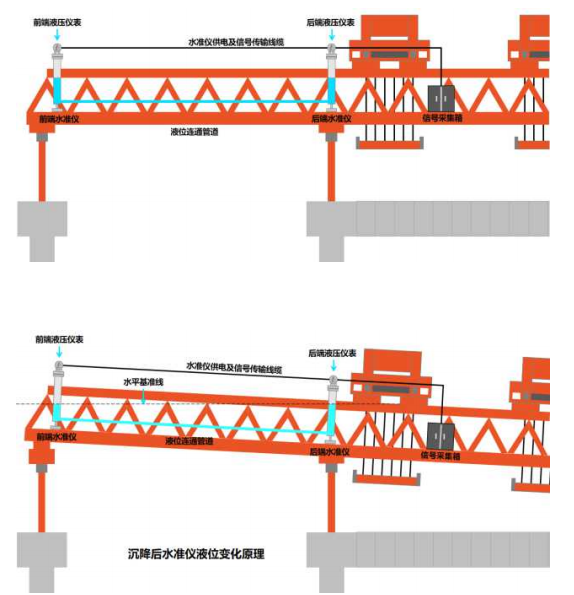

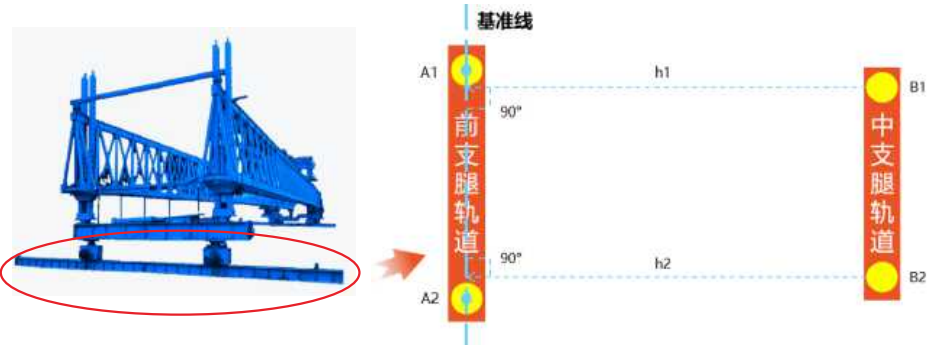

This time, we mainly focus on monitoring the front high and back low posture of the bridge girder erection machine during the hole and beam erection process, as well as the parallelism status of the front and middle support leg tracks during the transverse movement of the entire machine, in order to maintain a good operating posture of the bridge girder erection machine during the construction process, reduce safety risks caused by instability, and make the operation of the bridge girder erection machine safer and more efficient in management.

2. On site application issues and risks

During the use of the beam through hole, it is difficult to adjust and takes a long time to measure by manually pulling a ruler. The spacing between bridge piers is large, and the measurement error of the ruler is large; Personnel standing on the bent cap adjustment pose a high safety risk.

3. Technical solutions

Customers can monitor the parallelism posture of the track and observe the lengths of h1 and h2 displayed on the LED screen, as well as the difference between the two lines, to adjust the parallelism of the two track beams. Eliminates the process of manual ruler measurement and the high risk of measurement errors. The driver can check the height difference between the front and rear legs at any time through the value displayed on the height difference instrument, ensuring that the bridge erecting machine is always operating in a safe state.

4. Product and Service Delivery

The parallelism monitoring and height difference monitoring system developed and installed by Weite Technology Co., Ltd. can achieve precise ranging with an error control within millimeters.

Successfully solved the problems of difficult customer adjustment, large errors, and high risks. Successfully passed customer acceptance on site and received high praise from customers.

5. Use feedback

Throughout the entire project process, Weite adhered to the principle of customer first and successfully solved technical problems for customers. The product was accurately measured during use, and all functions met technical requirements and passed acceptance. At the same time, the customer acknowledges our company's products!