The following is the key illustration of the video!

A multi-dimensional analysis system for on-line fault diagnosis of cranes

In the operation of modern production enterprises, the losses caused by equipment failure and shutdown are very huge. Traditional equipment maintenance only relies on manual operation. The operation and maintenance work mainly adopts the "fire-fighting" mode of finding and solving problems. The preventive maintenance is poor, and it is difficult to reduce the failure rate. The prediction management has a long way to go.

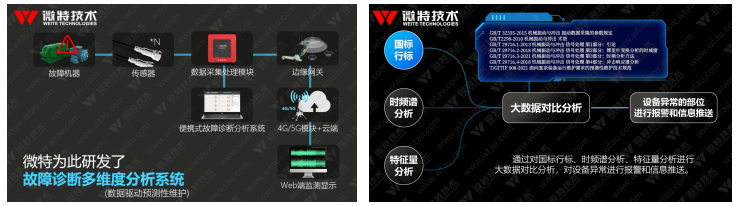

In view of the current market situation, Microtech has independently developed a multi-dimensional analysis system for fault diagnosis. Through big data comparison and analysis of national standard line standard, time-frequency spectrum analysis and feature quantity analysis, it alarms and pushes data for equipment abnormalities.

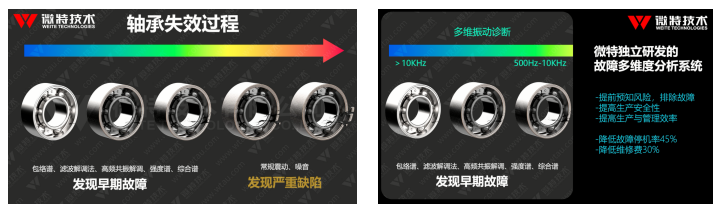

At present, in the market, the serious defects of bearings can be found by conventional vibration and noise. The fault multi-dimensional analysis system independently developed by Weite can detect the bearing fault at an early stage through envelope spectrum, filter demodulation method, high-frequency resonance demodulation, intensity spectrum and comprehensive spectrum. It can effectively improve production safety, improve production and management efficiency, reduce fault downtime rate by 45%, reduce maintenance cost by 30%, help enterprises reduce production, management and operation costs, and increase profits.

The multi-dimensional analysis system for micro and special faults is divided into three layers: equipment perception layer, big data analysis layer and monitoring management layer. It monitors the equipment status, predicts the fault risk, intervenes and eliminates the fault in advance, reduces the production management operation cost and improves the profit.

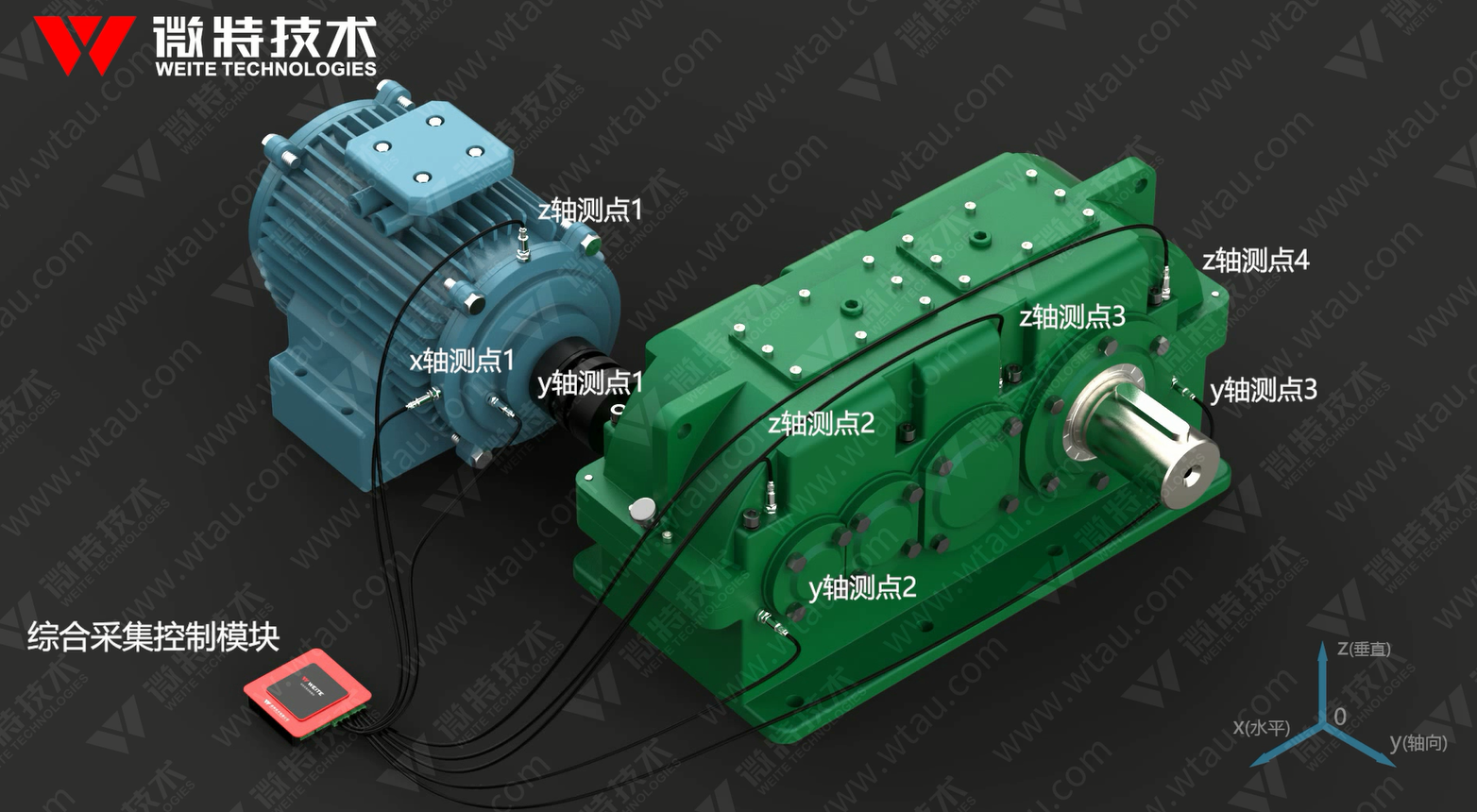

The micro special fault multi-dimensional analysis system installs vibration sensors at the designated positions of the motor and reducer.

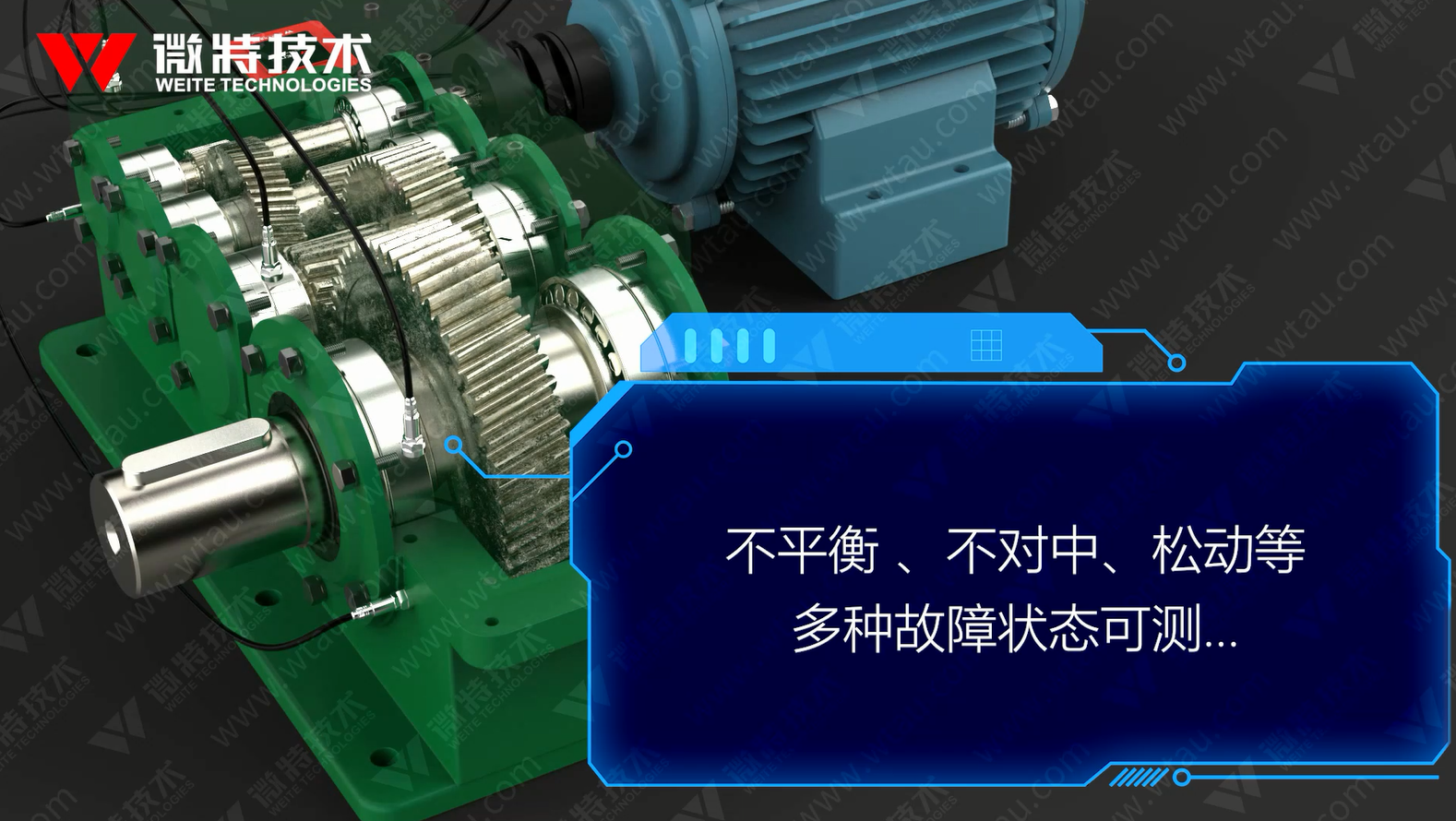

The system collects the vibration data of the motor and reducer, enters the system big data operation, develops the algorithm tool set specially for the complexity of the fault comprehensive spectrum, integrates a variety of time-frequency analysis methods to support the data analysis platform, realizes low-frequency and wide-range data analysis, dynamic data analysis, nonlinear and unstable fault feature extraction, fault diagnosis and fault prediction, and gives the fault diagnosis report.

Wt-msam-a2 integrated data acquisition and control module is an advanced high-precision data acquisition module designed for the multi-dimensional analysis system of micro and special faults. 8 / 16 channels of acquisition channel are optional, and independent IEPE excitation source is integrated to realize signal conditioning of acceleration sensor and other related signals. Each channel can be set independently by software. The on-board digital anti aliasing filter can effectively reduce high-frequency noise and suppress frequency aliasing.

At present, the micro special fault multi-dimensional analysis system has been successfully applied to the equipment of several large enterprise groups to accurately diagnose the equipment fault type, provide maintenance suggestions, and ensure the safe operation of the crane. Improve production safety, improve production and management efficiency, reduce fault downtime rate by 45%, reduce maintenance cost by 30%, help enterprises reduce production, management and operation costs, and increase profits.