3.1 safety monitoring system

The crane is a kind of super large and super high special lifting equipment. It has the characteristics of large crane volume, large lifting tonnage, high lifting height and complex construction environment. It is used to meet the needs of on-site production and assembly.

In the actual production and hoisting process, due to the complex site environment, all kinds of steel and structural parts can be seen everywhere, and the cranes on the same track are carrying out operations of different types of work at the same time. The characteristics of the above cranes determine that the crane operators must have a broad field of vision and know the current working parameters of the crane like the palm of their hands. However, the lifting work of large structural parts with the greatest difficulty is carried out on the crane, Or in the process of aligning the mechanical parts, the cooperation between the crane operator and the operator, the rapid docking of the mechanical parts and other requirements have become difficult problems in this operation, and the operation requirements and various data monitoring requirements for the crane operator will be further improved. Otherwise, the hoisting operation will take a lot of time and is very easy to occur hoisting accidents, which will endanger the safety of the crane, operators and ground personnel.

Therefore, the crane needs to install a comprehensive safety monitoring system for all working links, safety points, working conditions and instructions of the crane to ensure the safe operation of the lifting equipment, the safety of the operators, improve the work efficiency and reduce the safety hazards.

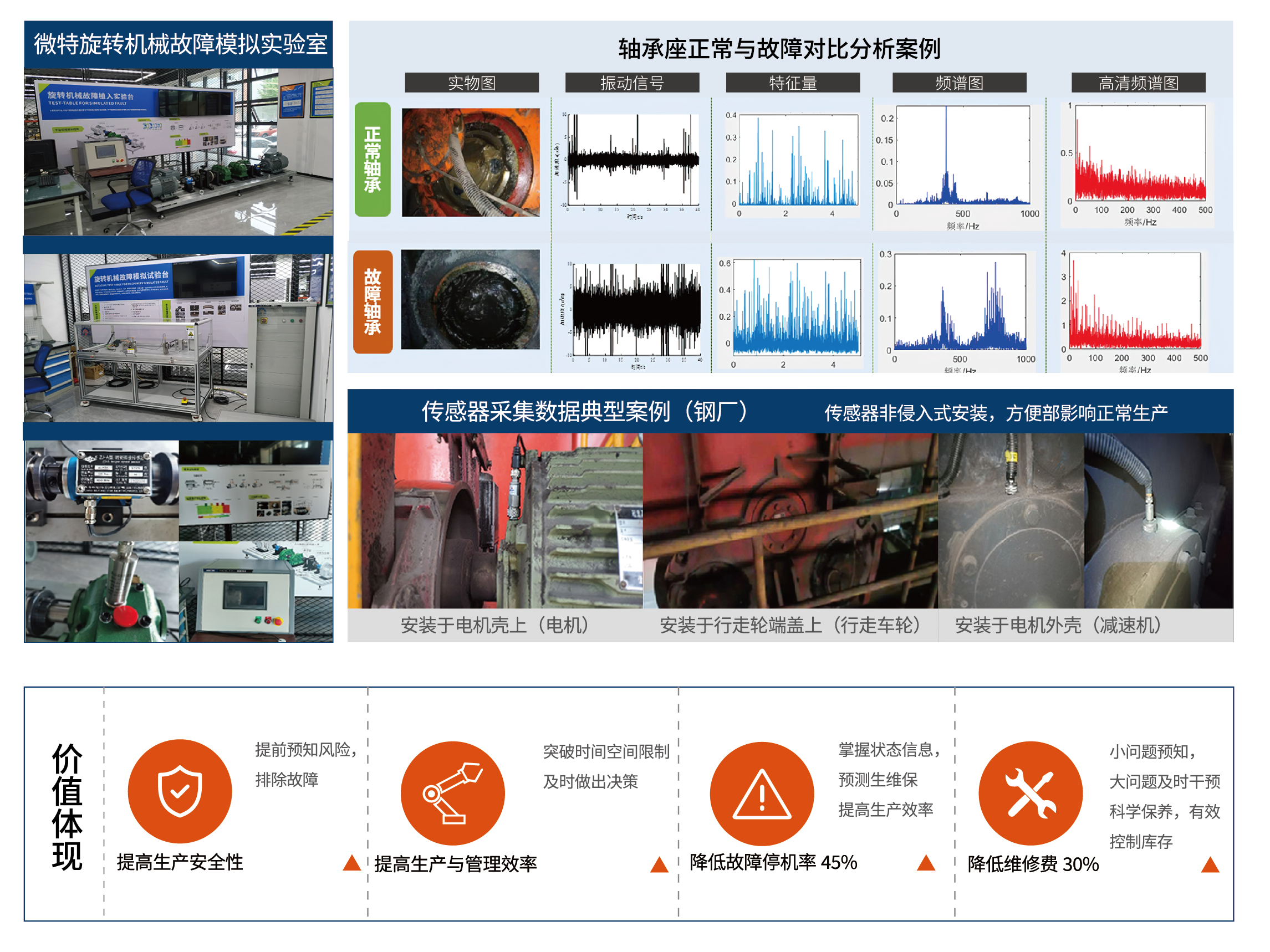

3.2 lifting equipment condition monitoring and early fault diagnosis system

Range of fault diagnosis prediction

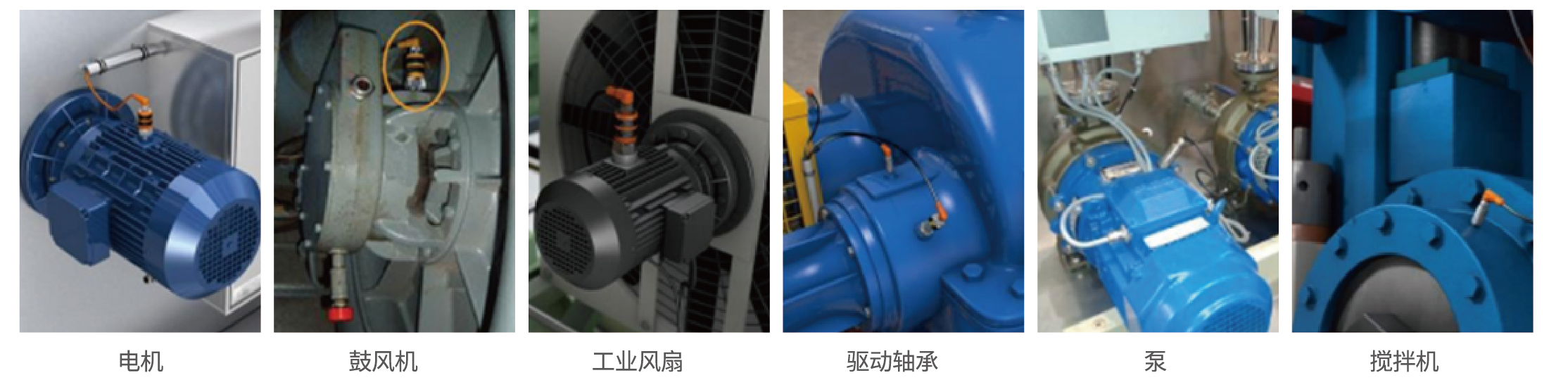

Generally speaking, mechanical equipment includes prime mover (such as electric motor), transmission system (such as gear transmission and hydraulic transmission) and execution system (machinery executed by terminal)

Function or action) the structural forms of the lifting motor and the gear transmission system are similar, but the scales are different. These two systems are also the most prone to failure,

Therefore, there are many researches on fault diagnosis methods and principles. The functions of the execution system are different, and the fault forms are more diverse and often related to its processes. Therefore, the execution

The fault diagnosis of the system is highly personalized.

The monitoring system of micro and special cranes pays more attention to fault diagnosis of gear transmission system. Mainly including: gear fault, bearing fault and rotating shaft fault; Gear faults mainly include broken teeth, tooth surface wear, pitch error, etc; Bearing (rolling) fault mainly includes inner ring, outer ring, rolling element and cage fault; Transmission shaft failure: shaft misalignment, excessive bending, fracture, etc. (relatively speaking, the failure rate is low).