According to the provisions of the special equipment safety law of the people's Republic of China and the special equipment safety supervision regulations, the national special equipment safety status in 2019 is hereby notified as follows.

1、 Basic information of special equipment

(1) Registration quantity of special equipment.

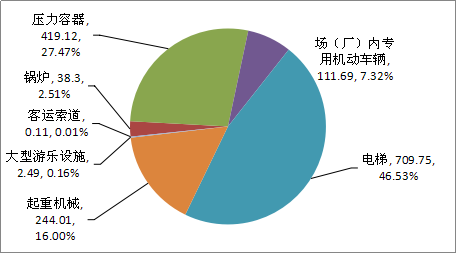

By the end of 2019, the total number of special equipment in China had reached 15.2547 million. Among them, there were 383000 boilers, 4191200 pressure vessels, 7.0975 million elevators, 2.4401 million lifting machines, 1089 passenger cableways, 24900 large-scale amusement facilities, and 1116900 special motor vehicles in the field (plant). In addition, there were 164 million gas cylinders and 561300 kilometers of pressure pipes. (see Figure 1)

Figure 1 Classification proportion of special equipment quantity in 2019

(2) Special equipment production and operation personnel.

By the end of 2019, there were 78111 special equipment production units (including design, manufacturing, installation, transformation, repair and gas filling) in China, with 80227 licenses, including 3634 design units, 3663 licenses, 17282 manufacturing units, 17905 licenses, 30470 installation, transformation and repair units, 30539 licenses, 27328 mobile pressure vessels and gas cylinder filling units 28120 licenses were held. (see Figure 2) special equipment operators have 12.1555 million certificates.

Figure 2 classification scale of special equipment production license in 2019

(3) Safety supervision, inspection and detection of special equipment.

By the end of 2019, there were 4161 special equipment safety supervision institutions in China, including 1 national level, 33 provincial level, 481 municipal level, 2552 county level, and 1094 district and county level agencies. There were 90164 special equipment safety supervisors nationwide.

By the end of 2019, there were 454 comprehensive inspection institutions for special equipment in China, including 270 inspection institutions within the system, 184 industry inspection institutions and enterprise self inspection institutions. In addition, there were 43 type test institutions, 563 non-destructive testing institutions, 2065 gas cylinder inspection institutions, 665 safety valve calibration institutions, and 310 lifting machinery inspection institutions at housing construction sites and municipal engineering sites.

In 2019, the national special equipment safety supervision departments at all levels carried out 2030400 person times of special equipment law enforcement supervision and inspection, and issued 133900 safety supervision instructions. The special equipment inspection organization supervised and inspected the manufacturing process of 1043900 special equipment and parts, and found and urged the enterprise to deal with 21000 quality and safety problems; Supervision and inspection were conducted on the installation, transformation and repair of 1576600 sets of special equipment, and 473000 quality and safety problems were found and supervised by enterprises. Regular inspections were carried out on 8.6137 million special equipment in use, and 1.9132 million quality and safety problems were found and urged to be handled by users, including 163000 pressure equipment problems and 1.7502 million electromechanical equipment problems.

2、 Safety status of special equipment

(1) General situation of the accident.

In 2019, there were 130 special equipment accidents and related accidents in China, with 119 deaths and 49 injuries. Compared with 2018, the number of accidents decreased by 37, a decrease of 22.2%, the number of deaths decreased by 34, a decrease of 22.2%, and the number of injuries decreased by 11, a decrease of 18.3%. The mortality rate of 10000 special equipment was 0.11. There were no major accidents throughout the year, and the safety situation of special equipment was generally stable.

(2) Accident characteristics.

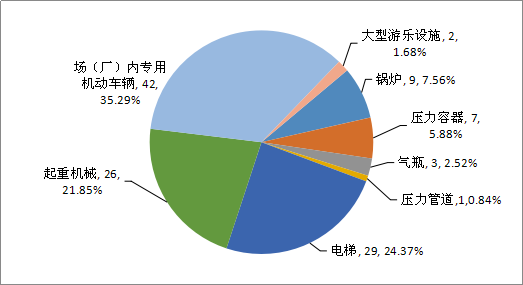

According to the equipment category, there were 11 boiler accidents, 9 deaths, 4 pressure vessel accidents, 7 deaths, 4 gas cylinder accidents, 3 deaths, 1 pressure pipeline accident, 1 death, 33 elevator accidents, 29 deaths, 26 hoisting machinery accidents, 26 deaths, 45 special motor vehicle accidents in the field (plant), 42 deaths, 6 large amusement facilities accidents and 2 deaths. (see Fig. 3 and Fig. 4) among them, the top three equipment in the number of accidents are special motor vehicles, elevators and lifting machinery in the field (plant), all of which are electromechanical special equipment, accounting for 80.00% of the total number of accidents and 81.51% of the total number of deaths.

Figure 3 number and proportion of special equipment accidents in 2019

Figure 4 death toll and proportion of special equipment accidents in 2019

According to the occurrence link, 109 cases occurred in the use link, accounting for 83.85%; There were 16 maintenance links, accounting for 12.31%; There were 3 installation and disassembly links, accounting for 2.31%; 1 filling and transportation link, accounting for 0.77%; There was one manufacturing link, accounting for 0.77%. (see Figure 5)

Figure 5 distribution and proportion of special equipment accidents in 2019

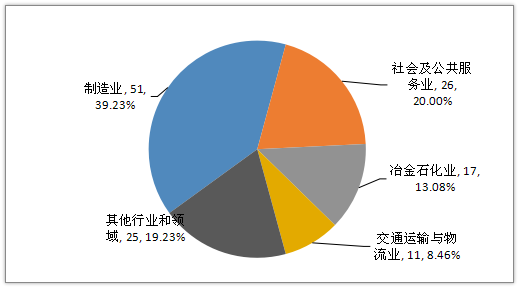

According to the industries involved, 51 cases occurred in the manufacturing industry, accounting for 39.23%; 26 cases occurred in the social and public service industry, accounting for 20.00%; 17 cases occurred in metallurgy and petrochemical industry, accounting for 13.08%; 11 cases occurred in the transportation and logistics industry, accounting for 8.46%; There were 25 cases in other industries and fields, accounting for 19.23%. (see Figure 6)

Figure 6 industrial distribution and proportion of special equipment accidents in 2019

According to the damage form, the main characteristics of pressure equipment (boiler, pressure vessel, gas cylinder and pressure pipeline) accidents are explosion, leakage and fire; The main characteristics of accidents of electromechanical equipment [lifting machinery, elevators, large amusement facilities, special motor vehicles in the field (plant)] are falling, collision, extrusion, shearing, etc.

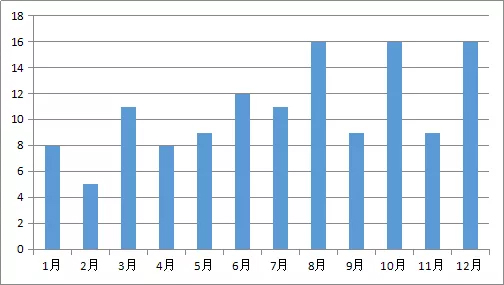

According to the month of occurrence, the number of special equipment accidents is the lowest in February, and the number of special equipment accidents is the highest in August, October and December. (see Figure 7)

The main reason is that during the Spring Festival holiday in February, the industrial, mining and trade industries were shut down and the accidents were relatively low; August and October are summer holidays. The safety awareness of personnel is lax. There are loopholes and blind spots in online monitoring, hidden danger investigation, safety management and other aspects, and accidents are relatively frequent; As December approaches the end of the year, many industries have problems such as rush hour and cross operation, and accidents are relatively frequent.

Figure 7 distribution of special equipment accidents from January to December 2019

(3) Cause of the accident.

By the end of 2019, a total of 93 special equipment accidents had been closed. According to the analysis of the closing materials, the causes of the accidents were mainly divided into three categories. First, accidents occurred due to improper use and management, accounting for about 87.10% of the total number. Illegal operation is still the main cause of accidents, which is manifested in illegal operation, improper operation or even unlicensed operation, lack of maintenance and poor management. Second, accidents caused by quality and safety defects in equipment manufacturing, maintenance and repair, installation and disassembly and operation accounted for about 8.60%. Third, accidents caused by other secondary causes, accounting for about 4.30%. (see Figure 8)

Figure 8 distribution of special equipment accident causes in 2019

The accident causes are classified as follows by equipment:

1. Boiler accident. 1 case of illegal operation or improper operation, 3 cases of unlicensed operation, 1 case of equipment defect and safety accessory failure, and 3 cases of other secondary reasons.

2. Pressure vessel accident. 1 case of illegal operation or improper operation.

3. Gas cylinder accident. There was 1 case of inadequate safety management and maintenance, and 1 case of other secondary reasons.

4. Pressure pipeline accident. Safety management and maintenance were not in place in 1 case.

5. Elevator accident. There were 9 cases of illegal operation or improper operation, 1 case of unlicensed operation, 4 cases of equipment defect, safety component failure or protection device failure, 2 cases of improper emergency rescue (self rescue), and 8 cases of inadequate safety management and maintenance.

6. Hoisting machinery accident. There were 14 cases of illegal operation or improper operation, 1 case of unlicensed operation, and 3 cases of equipment defect, safety component failure or protection device failure.

7. Accidents of special motor vehicles in the yard (plant). There were 24 illegal operations or improper operations, and 10 unlicensed operations.

8. Accidents of large amusement facilities. There were 3 cases of illegal operation or improper operation and 2 cases of unlicensed operation.

3、 Main work of special equipment safety supervision and energy saving in 2019

First, we should firmly adhere to the bottom line of security and ensure that the security situation is stable and good. It organized the investigation and treatment of special safety hazards of special equipment related to hazardous chemicals, liquefied petroleum gas cylinders, pipelines within the scope of power station boilers, large amusement facilities and passenger cableways, and eliminated 256336 safety hazards of various special equipment throughout the country. It organized and promoted the research on welding process and testing standards of X80 steel grade natural gas pipelines, and achieved phased results.

Second, the reform of decentralization, management and service was carried out in depth, with remarkable results in various work. Streamline, consolidate and delegate special equipment licensing projects, and reduce 132 licensing projects of production units, a decrease of 54%; The number of qualification identification items for operators decreased by 35, with a decrease of 64%; The provincial market supervision department was delegated to implement 8 subprojects of inspection and testing personnel. We will further improve the licensing work system, optimize the licensing work process, and implement the self declaration commitment and review free license replacement system to effectively reduce the institutional transaction costs of enterprises.

Third, we explored innovation in elevator supervision and achieved initial results in safety co governance. Vigorously promote elevator safety liability insurance and constantly explore new models of elevator insurance. By the end of 2019, 2.7316 million elevators had been covered by various types of elevator liability insurance nationwide, accounting for 38.49% of the number of elevators in use, exceeding the annual target.

Fourth, we will deepen the support mechanism for major events and successfully complete various support tasks. We will coordinate the service and support of special equipment for major events such as the 70th anniversary of the founding of new China and the seventh military games, and establish a joint defense and governance mechanism for special equipment safety between the host of major events and surrounding provinces.

At the same time, a series of basic work has been strengthened and the regulatory efficiency has been further improved. Improve the system of regulations and standards, and organize the preparation and revision of safety technical specifications such as rules for type test of lifting appliances and rules for energy efficiency test and evaluation of heat exchangers. Strengthen the informatization construction of special equipment, and carry out the pilot application of elevator quality and safety traceability information platform in some provinces and cities; The construction of gas cylinder quality and safety traceability information platform was accelerated; The mobile pressure vessel quality and safety traceability information platform was initially completed; Realize the real-time query of equipment type test report on the Internet. Strengthen education and training, organize the production of training videos and teaching materials, organize the boiler energy conservation and environmental protection training, and improve the professional ability and technical level of grass-roots safety supervisors. Strengthen international exchanges and promote the establishment of standards cooperation mechanisms. Organize and carry out elevator safety publicity, make publicity videos and public service advertisements for safe riding, which are widely reprinted and disseminated by the media and have achieved good publicity results.

It is hereby notified.

▲ the above information is from the official website of the State Administration of market supervision and administration