2019 marks the 70th anniversary of the founding of new China. 70 years of hard work, 70 years of trials and hardships. China's construction industry has gone through an extraordinary development path and made brilliant achievements that attract worldwide attention. At present, the construction capacity and technical level of China's construction industry have entered the world's advanced ranks, and a large number of high, large, fine and advanced projects have been built. The successful construction of these large and super large projects reflects that China's construction industry has excellent design and construction capabilities, and can proudly stand among the world's architectural powers. On this festival, the whole country is celebrating, and the construction technology has launched a special report on "70 years of struggle, brilliant construction road", to present a gift to the great motherland and wish the motherland forever green!

Since the founding of new China 70 years ago, China's hydropower industry has undergone earth shaking changes. It has developed synchronously with the national economy and made important contributions to accelerating the process of building a moderately prosperous society and a beautiful China in an all-round way. China's hydropower development scale and technical difficulty are constantly creating various world firsts. With exquisite technology and fine management, it has built the world-famous Three Gorges Hydropower Station on the Yangtze River and a number of world-class large hydropower projects such as Xiluodu, Xiangjiaba, Xiaowan, Shuibuya, Nuozhadu, Goupitan and Jinping, and a number of internationally leading Mega hydropower projects such as Baihetan and Wudongde are under construction. The construction of the world's largest hydropower station dams requires a series of advanced engineering technology support, such as high dam engineering technology, high slope stability technology, underground engineering construction technology, long tunnel construction technology, flood discharge and energy dissipation technology, and high dam seismic technology. It can be said that in all these engineering technologies, China has already walked in the forefront of the world.

At present, the largest hydropower station in the world is the Three Gorges hydropower station which was completed and put into operation in 2003; The highest roller compacted concrete dam (216 meters) is the Longtan hydropower station put into operation in 2007; The highest concrete face rockfill dam (233m) is the Shuibuya hydropower station put into operation in 2008; The highest double curvature arch dam (305 meters) is the Jinping I Hydropower Station completed and put into operation in 2013. At present, the rockfill dam of Shuangjiangkou Hydropower Station under construction in China will reach 312 meters in height. After completion, it will become the highest dam in the world, breaking all world records.

Sanmenxia Hydropower Station

The first large hydropower station in New China

The Sanmenxia water conservancy project, known as the "first dam of the Yellow River", is the first large-scale water conservancy project built on the Yellow River after the founding of new China. It controls the drainage area of 688400 square kilometers, accounting for 91.5% of the total drainage area, and controls 89% of the Yellow River's water and 98% of its sediment. The project was built in 1957 and basically completed in 1960. The main dam is a concrete gravity dam, with a length of 713.2 meters, a maximum dam height of 106 meters, and a total installed capacity of 400000 kilowatts. It is a large national hydropower enterprise.

In terms of design, Sanmenxia hydroproject has accumulated many useful experiences. A systematic theory has been gradually formed for the planning of building reservoirs on sediment laden rivers. This is a leap compared with the little knowledge of river sediment during the planning of the Yellow River in the early days of the founding of new China. At present, there are relatively mature calculation principles and methods, including that the water conservancy project should have sufficient discharge and sediment discharge scale, and the reservoir should adopt the operation mode of "storing clear water and discharging muddy water" to regulate water and sediment and improve the comprehensive utilization efficiency of the water conservancy project.

Xin'anjiang hydropower station

It is the first large-scale hydropower station designed and built by itself after the founding of new China

Xin'anjiang hydropower station is located in Tongguan gorge, 6km west of Xin'anjiang Town, Jiande City, Hangzhou, Zhejiang Province. Xin'an River is famous for its many beaches and rapid water. Huang Jingren, a poet of the Qing Dynasty, described its majestic momentum with the poem "one beach after another, one beach is ten feet high. 360 beaches, Xin'an is in the sky".

Before the founding of new China, the Qiantang River Water Conservancy Survey Office submitted a survey report to the executive yuan of the national government. However, under the rule of the Kuomintang, China's political corruption and national strength are weak, and no matter how good the idea is, it can only become a dream. At that time, Xu qiaoshi, a water conservancy expert who presided over the Qiantang River Water Conservancy Survey Office, did not realize his long cherished wish until he served as the chief engineer of Xin'anjiang hydropower engineering bureau in New China.

In 1952, the new people's government started the survey, research and development demonstration of Xin'anjiang hydropower station again. After several discussions, the scheme of the hydropower station with an installed capacity of 662500 kilowatts was finally determined.

In April 1957, the Xin'anjiang hydropower station was started.

Xu Qishi, one of the founders of China's hydropower technology and chief engineer of Xin'anjiang hydropower station, adopted the ski type roof overflow arrangement in the design of the hydropower station, which opened up a way for China to arrange hydraulic hubs in the canyon.

Pan Jiazheng, son of Jiang River and deputy chief engineer of Xin'anjiang hydropower station, creatively changed the original designed solid gravity dam into a wide joint gravity dam. There are 20 wide joints in the dam, and the power station is built under 9 flood discharge holes. This structure can reduce the uplift pressure of the dam foundation, save a large amount of concrete, and facilitate personnel to enter the cavity of the wide joint for inspection and maintenance of the dam body and the dam foundation. These new technologies have brought great economic and social benefits to the hydropower construction in China.

Xin'anjiang hydropower station is a monument in China's water conservancy and power industry. It has accumulated valuable experience for the construction of large-scale hydropower stations in the country, and has also imported a large number of talents for many large and medium-sized hydropower stations in China. It is known as the "experimental field of the Three Gorges of the Yangtze River".

Gezhouba Hydropower Station

Gezhouba is known as the first dam on the Yangtze River. It is the first large-scale hydropower project on the main stream of the Yangtze River. It is known as a milestone in the history of China's hydropower development in the 20th century.

Gezhouba hydropower station was not only the largest hydropower station in China at that time, but also the first hydropower station on the main stream of the Yangtze River. It was almost unprecedented in terms of the difficulty of river closure. The installed capacity of the power station was 2.7 million kilowatts and the annual power generation of 14 billion kilowatt hours, accounting for about one-third of the total installed capacity and total power generation of hydropower in China at that time, providing a huge power and guarantee for the economic and social development of East China.

In order to ease the tight situation of industrial power consumption in Central China at that time as soon as possible, in December 1970, the central government officially approved the construction of Gezhouba Water conservancy project, which was located at the end of the Yangtze River Three Gorges in Yichang City, Hubei Province, 2.3 kilometers downstream of nanjinguan, the outlet of the Yangtze River Three Gorges.

In order to ensure the normal navigation of the Yangtze River channel, prevent sediment deposition and do a good job in the Yangtze river closure, the engineering and technical personnel at that time used a reduced scale model to simulate the terrain and water flow changes in this area. Finally, after repeated tests and demonstrations, they adopted the pattern of one body and two wings, and successfully solved the problem of flood discharge and sediment discharge according to the scheme of "still water navigation and dynamic water flushing"; The engineering personnel also used the method of single berm vertical blocking to successfully realize the Yangtze River Closure in only 36 hours. This is the first Yangtze River Closure in history and also an innovation in the history of water conservancy construction in China.

Three Gorges Hydropower Station

The Three Gorges project is one of the most magnificent water conservancy and hydropower projects in the world. It has been a long 85 years since the Three Gorges project was put forward and the first batch of water turbine generator units of the Three Gorges Hydropower Station generated electricity. This is not only a history of ups and downs, but also a history of vigorous and vigorous development of the great creative spirit of the Chinese people.

Although the Gezhouba project has realized the river closure for the first time, it is obviously much more difficult to close the Three Gorges Project. On November 8, 1997, the Three Gorges project realized the river closure; On November 6, 2002, the diversion open channel of the Three Gorges project was successfully closed. The Three Gorges project has cut off the Yangtze river twice, indicating that China's closure technology is leading in the world. According to the technical scheme proposed by Zheng Shouren, a water conservancy expert, the Three Gorges project has been successfully intercepted twice in the construction process, which is rare in the world. "Research and engineering practice on design and construction technology of river closure of the Three Gorges Project" won the first prize of national science and technology progress.

Compared with the closure project with the highest single hydraulic index in the world, the three key hydraulic indexes of flow, drop and velocity of the Three Gorges Project are relatively high, and its comprehensive difficulty is rare in the world closure history. The success of two river closure indicates that China's river closure technology has entered the leading position in the world. The river closure design of the Three Gorges project won the National Excellent Design Gold Award, and its technical achievements won the first prize of the national science and Technology Progress Award in 2000.

The concrete work volume of the Three Gorges project is huge, with a total volume of 28 million cubic meters, of which the dam concrete pouring volume is 16 million cubic meters, and the peak construction intensity requires more than 5 million cubic meters of concrete to be poured in a year. A large number of the latest technologies and techniques have been applied in the concrete pouring, so that the dam concrete pouring technology has reached the international first-class level.

New concrete raw materials and mix proportion. The Three Gorges project took the lead in China to use the granite excavated from the project itself as artificial aggregate for concrete after crushing. For the first time, the first-class fly ash with excellent performance was used as concrete admixture, and several million yuan was invested to study the concrete mix ratio, including further improving the high-performance additive, so that the comprehensive performance of the concrete reached the optimal level.

Revolutionary concrete pouring scheme. Concrete pouring scheme and matching technology are the key to dam concrete construction. In the past, the traditional pouring process of intermittent truck transportation and crane bucket warehousing was often used for dam concrete construction. The Three Gorges Corporation introduced the most advanced foreign special equipment for dam pouring, tower belt machine. However, tower belt conveyor is a new equipment developed in the 1980s, and there is not much mature experience abroad. In the actual use, the Three Gorges project has continuously innovated and summarized a complete set of construction technology to ensure the quality. With this set of technology, the Three Gorges project not only broke the world record of annual concrete pouring volume for three consecutive years, but also the dam concrete quality was generally good.

Innovative concrete temperature control and crack prevention technology. Temperature control and crack prevention of mass concrete is a long-standing problem in dam construction. In the construction of the Three Gorges project, the secondary air cooling technology of concrete aggregate was first developed. In midsummer, all the concrete produced by the mixing plant shall be pre cooled to 7 ℃, and the high-grade concrete shall be "personalized" cooled by water; Three early warning systems of "weather, temperature control and intermittent period" are creatively formulated to ensure the quality of each link of concrete temperature control. In 2002, the cracks of the Three Gorges dam were exposed by the media, and experts diagnosed the cracks as temperature cracks that develop toward the shallow layer, rather than structural cracks. The construction party and the management party handled this problem in a timely manner. During the construction of the third stage, there was no crack in the dam on the right bank, creating a miracle in the world's hydropower industry.

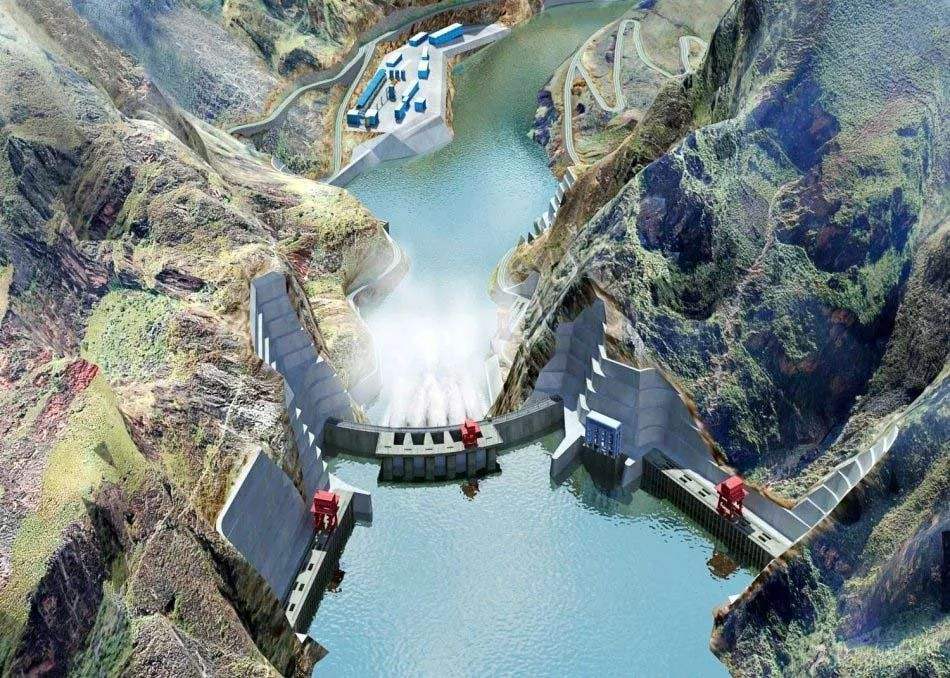

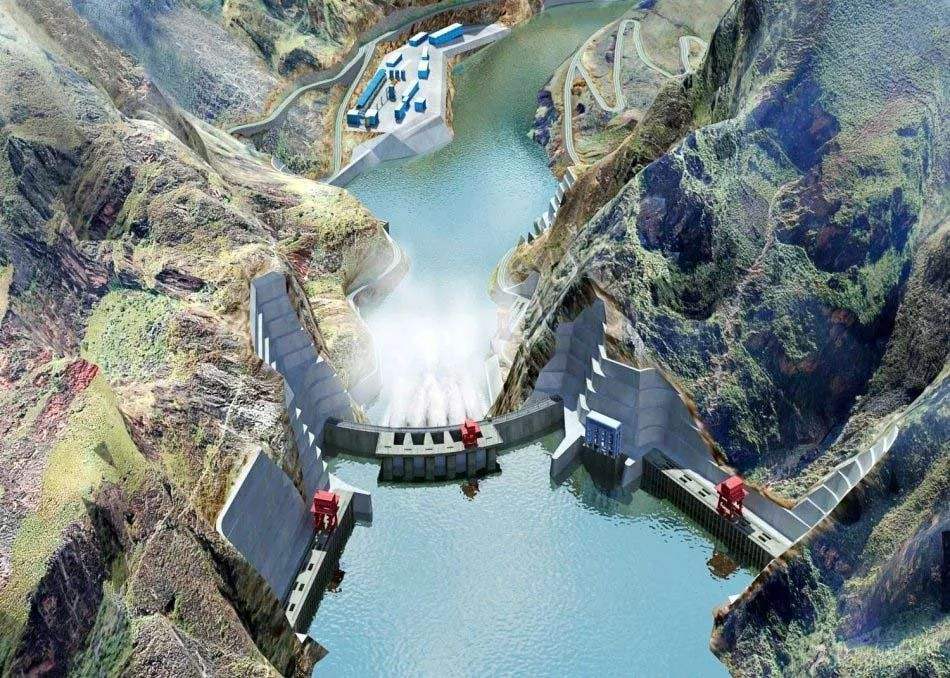

Wudongde Hydropower Station

It is the fourth super hydropower station in China and the seventh super hydropower station in the world that has entered the ranks of ten million kilowatts

Wudongde Hydropower Station has entered the construction stage of the main project since December 24, 2015, and has been under construction for four years. The construction of the hydropower station with the highest dam of 270 meters is faced with many engineering problems, and the builders have created numerous engineering miracles here.

The dam of Wudongde Hydropower Station is 270 meters high and is a concrete double curvature arch dam, which is the highest double curvature thin arch dam in the world. The thickness of the dam bottom is only 51 meters. This proportion makes Wudongde Hydropower Station the thinnest 300 meter arch dam in the world at present, and its slender body is required to carry the water storage of tens of millions of super large hydropower stations. For this reason, low heat cement concrete is used for the whole dam, and low heat cement is used for the whole dam body. This is the first time, and it is also an innovation in the history of dam construction in the world.

Wudongde Hydropower Station dam is known as the most "smart" dam in the world. Many new scientific and technological innovations have been applied to the dam, such as special thermometer, cooling artifact, dam "eye" and one key "grouting". Through the real-time monitoring of the dam's health, and through a number of independent and innovative intelligent technologies such as intelligent water supply, intelligent grouting and intelligent spray, it shows the highest level of intelligent construction of China's dam building technology and leads the construction of hydropower projects into the era of intelligent construction 2.0.

Wudongde Hydropower Station is planned to close the gate and store water in October 2019, and the first batch of units will be put into operation in July 2020.

Concluding remarks

Looking back on the history, Sinohydro has striven forward for 70 years, and has achieved fruitful results through trials and tribulations. Today, although we have reached the peak of the world's hydropower, looking ahead to the future, the mission of promoting energy transformation and fulfilling the commitments of the Paris Agreement is arduous. China's hydropower still has a long way to go. All hydropower workers will strive to enter the new era and write a chapter of hydropower in the new era.

(source: wechat official account water conservancy home)