Recently, the application projects of Weite's non-destructive testing system for steel wire ropes in three major automotive companies, Dongfeng, Guangqi, and Chang'an, have been successively accepted, marking the successful entry of Weite products into the automotive manufacturing industry. The smooth implementation of this batch of projects is not only a demonstration of Weite's down-to-earth and dedicated manufacturing capabilities, but also an important milestone for Weite in providing solutions and technologies for intelligent automotive production workshops and digital factories in the manufacturing industry.

Chang'an Automobile

Weite's non-destructive testing system for steel wire ropes has been successfully applied in the Avita workshop of the Liangjiang factory in Chang'an, Chongqing. AVITR is a high-end intelligent electric brand jointly created by Chang'an, Huawei, and Ningde Times.

GAC Toyota

Weite's wire rope non-destructive testing system has been successfully applied to Guangzhou Automobile Toyota Huangge First Factory, which is Toyota's overseas model factory and has strict control standards during the production process.

Dongfeng Motor

The Weite non-destructive testing system for steel wire ropes has been successfully applied to the Xiangyang factory of Dongfeng Automobile Light Commercial Vehicle Branch. Dongfeng Light Commercial Vehicle Branch adheres to the brand mission of "leading light vehicle enterprise in customer experience", producing models including light trucks, light buses, bus chassis, new energy logistics vehicles, etc.

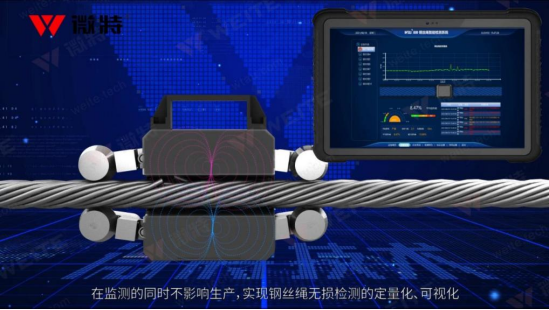

In highly automated automotive production lines, automated management of crane wire ropes is indispensable. The successful acceptance of the application project of the micro special steel wire rope non-destructive testing system in the three major automobile enterprises of Dongfeng, Guangqi, and Chang'an marks the further improvement and recognition of micro special company's technical strength in the manufacturing industry.

The maintenance and management of steel wire ropes for lifting equipment is a difficult task for equipment management in various enterprises. Accidents caused by wire rope breakage are accompanied by serious consequences such as property damage and casualties. The micro special steel wire rope non-destructive testing system has the characteristics of "efficiency, accuracy, convenience, and safety", providing customers with scientific and effective steel wire rope maintenance solutions. This system can not only be used independently, but also interface with the intelligent maintenance platform of factory equipment, providing important steel wire rope health data and analysis reports to the platform. The micro special steel wire rope non-destructive testing system will be a crucial component of future smart factory management.