In August 2017, the 900t beam carrier deviation correction monitoring system developed by Weite electronics successfully completed the installation and commissioning in the Damiao laying and erecting branch of Xuyan project of China Railway 12th Bureau, and was unanimously recognized by customers.

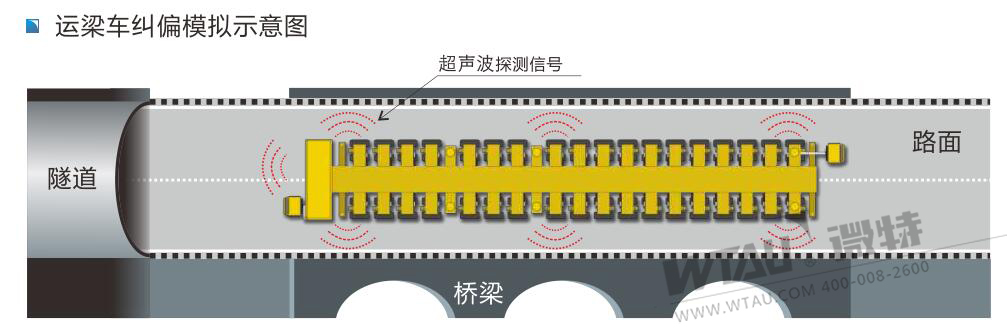

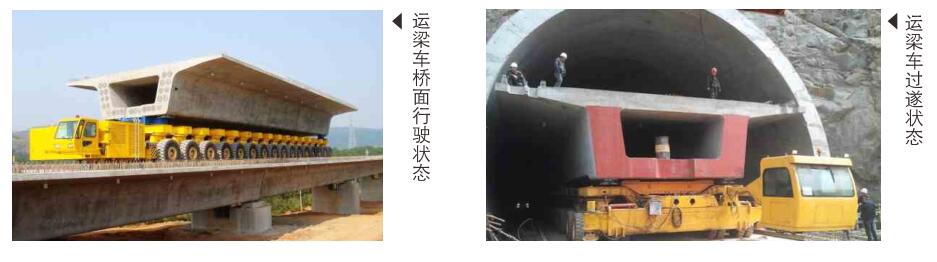

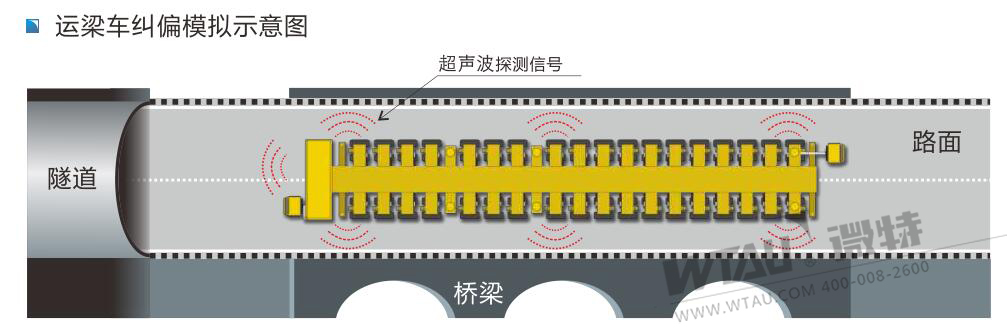

Due to the long body and large load capacity of the beam carrier, it is necessary to ensure consistency before the construction section, especially when passing through bridges, tunnels and other sections. It is impossible to avoid the deviation and other problems in the driving process by manual driving. The installation of the deviation correction monitoring system can detect the running route of the beam carrier in real time and automatically track and correct the deviation, so as to ensure the traveling route of the beam carrier and improve the beam erection efficiency.

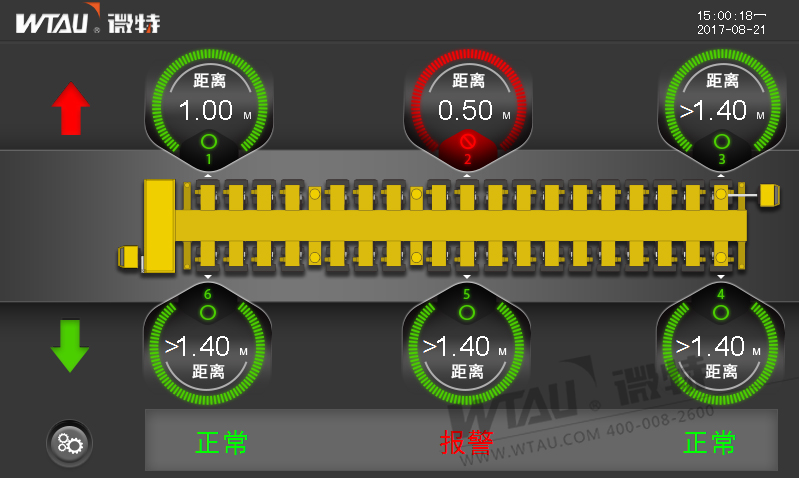

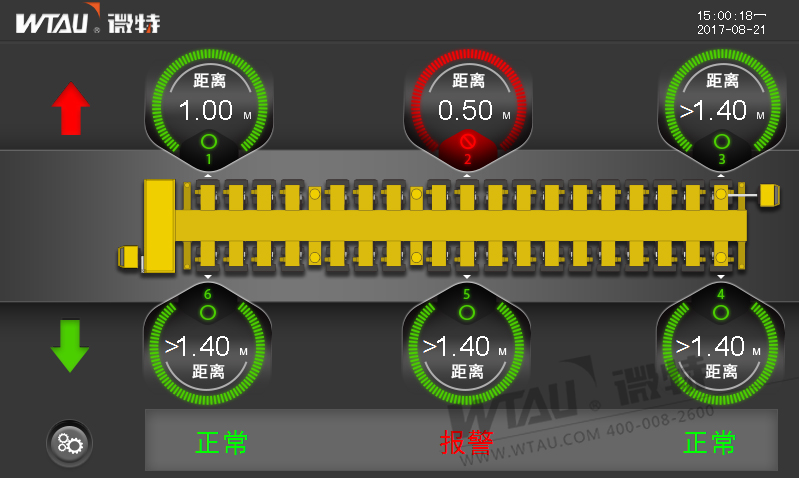

The system is to install six ultrasonic sensors on the left and right sides of the front, middle and rear sections of the beam transport vehicle to detect the actual distance between the beam transport vehicle and the reinforcement prefabricated parts on both sides during the traveling process, compare the distance data on the left and right sides, display the detected distance data on the display screen, and give an alarm prompt for the deviation of the beam transport vehicle. The alarm control point can be set in the instrument menu. Collect the signal of the original laser distance sensor on the beam carrier, detect the alignment distance between the beam carrier and the bridge erecting machine, and give the display and alarm prompt.

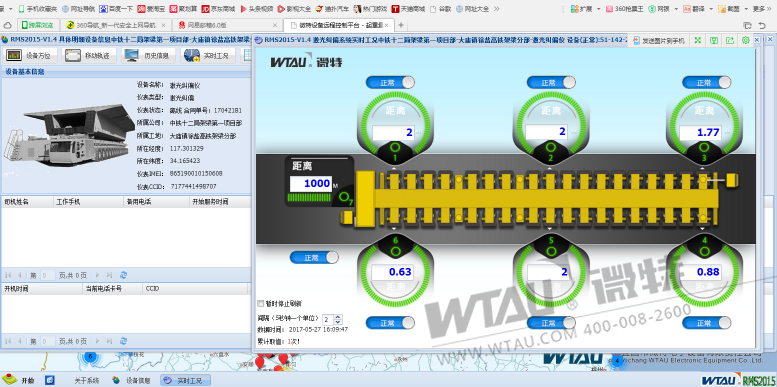

The system not only displays the operation data in the front and rear cabs. A remote data transmission interface is also reserved. The operation status of the beam carrier can be transmitted to the cloud server through the GPRS module, and the real-time status of the beam carrier can also be viewed through the mobile phone or PC.

Front cab display instrument

Display interface

Remote platform display interface